article on the impact of advanced cutting tools in the manufacturing industry.

Advanced Cutting Tools are Revolutionizing the Manufacturing Industry

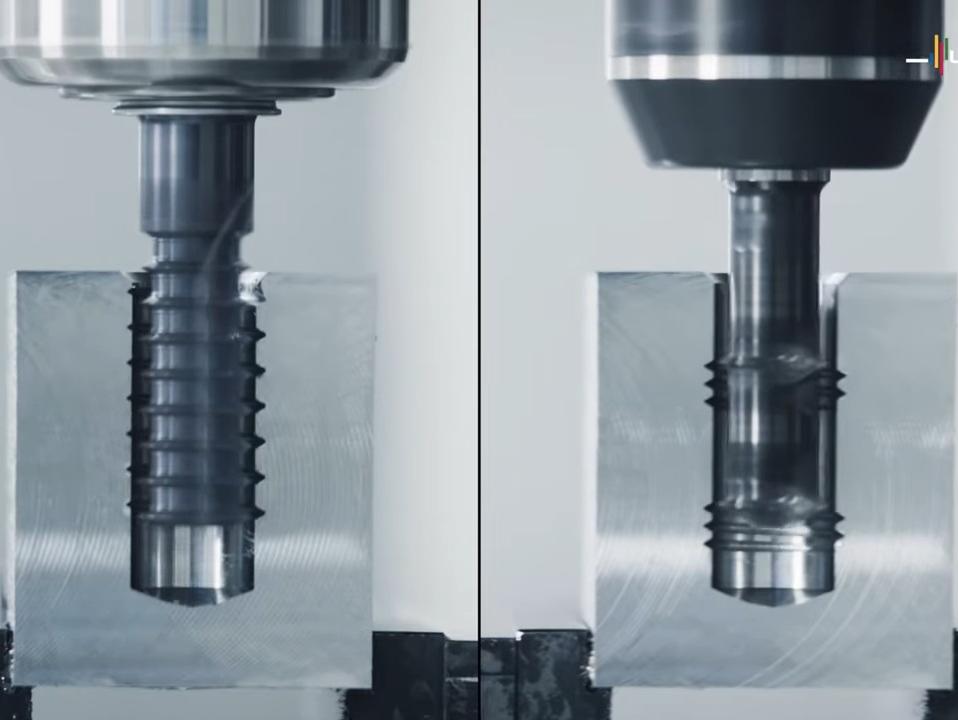

Cutting tools are at the heart of the manufacturing industry. From drilling, milling, turning to sawing, every operation relies on cutting tools to shape and form materials. In recent years, the advent of advanced cutting tools has revolutionized the way manufacturers operate. These tools are more precise, efficient, and durable, allowing manufacturers to produce high-quality products at a lower cost.

One of the companies leading the charge in this field is Walter USA, Inc. The company has recently launched a new solid carbide milling cutter with a corner radius that is set to further enhance the efficiency and accuracy of manufacturing processes. With a focus on meeting the needs of its customers, Walter USA has built a reputation for excellence in terms of quality, reliability, and customer service.

Advanced cutting tools have come a long way since the days of manual cutting and shaping. Today's tools incorporate advanced technologies such as computer-aided design (CAD), artificial intelligence (AI), and automation to deliver superior results. The use of advanced materials like tungsten carbide, ceramic, and diamond coatings has significantly increased the durability and lifespan of cutting tools.

The introduction of CNC machines and other high-tech equipment has also boosted the precision and efficiency of cutting tools. This has enabled manufacturers to produce complex shapes and parts with a high degree of accuracy, reducing the need for manual labor and increasing productivity.

The benefits of advanced cutting tools are not limited to manufacturing efficiency, however. They also have a positive impact on the environment by reducing waste and energy consumption. Precision cutting minimizes material wastage, while automation and optimization of production processes reduce the need for energy-intensive manufacturing methods.

The increased adoption of advanced cutting tools has also led to the development of new applications and industries. From aerospace and automotive to medical and electronics, manufacturers across a wide range of sectors are discovering the benefits of these tools. For example, in the medical industry, cutting tools are used to manufacture precision surgical instruments, implants, and prosthetics.

In the automotive industry, cutting tools are used to produce engine parts, gears, and other components. Advanced cutting tools have helped manufacturers to reduce the weight of vehicles by using lighter materials like aluminum, which has in turn led to improved fuel efficiency and reduced emissions.

In the aerospace sector, cutting tools play a critical role in the manufacture of aircraft parts, turbines, and other components. The precision, speed, and durability of advanced cutting tools are essential in the production of high-performance aircraft.

The application of advanced cutting tools is also leading to new concepts and technologies in manufacturing. For instance, additive manufacturing, also known as 3D printing, is a rapidly evolving field that utilizes cutting tools to produce intricate and complex shapes.

Additive manufacturing is becoming increasingly popular in industries such as aerospace and medical, where precise and customized parts are in demand. The use of cutting tools in additive manufacturing has also enabled manufacturers to work with a wide range of materials, including metals, polymers, and ceramics.

The impact of advanced cutting tools on the manufacturing industry is undeniable. From enhancing manufacturing efficiency and precision to creating new applications and industries, these tools are revolutionizing the way we make things.

As the industry continues to innovate and adapt to new technologies, it is clear that advanced cutting tools will play an increasingly important role in shaping the future of manufacturing. Companies like Walter USA are at the forefront of this evolution, developing cutting-edge tools that will continue to set new standards for quality, efficiency, and sustainability in the industry.